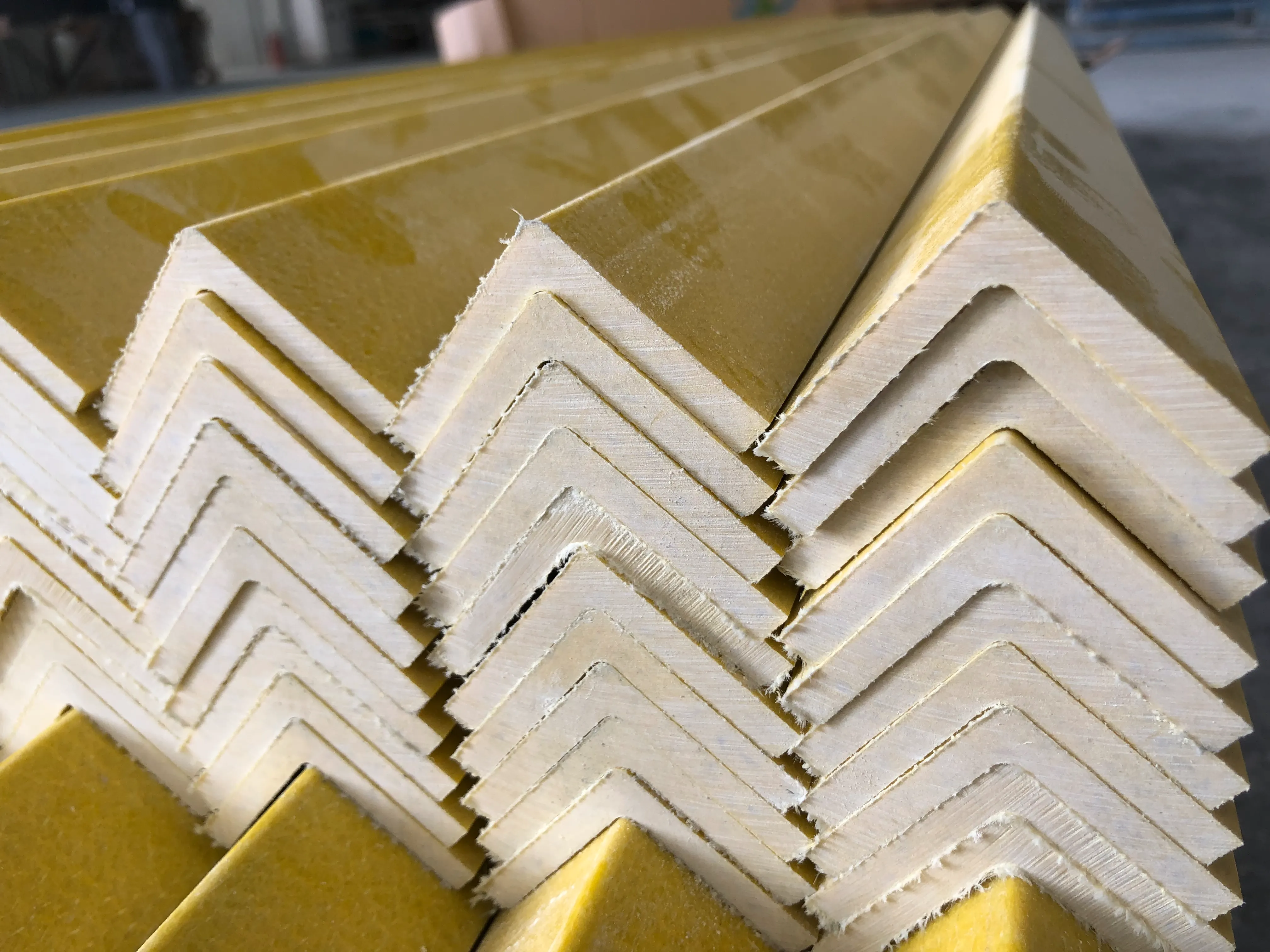

frp bridge deck

Links

HPMC's solubility characteristics allow it to be used in various applications, including

In conclusion, redispersible polymer powders play a pivotal role in enhancing the performance of various construction materials. Understanding the different types of RDPs and their specific applications allows manufacturers to make informed choices, ensuring that the end products meet the desired performance standards. As the construction industry continues to evolve, RDPs will remain integral to developing innovative materials that cater to dynamic building needs.

Consuming the Capsule

Density, in a general sense, is defined as mass per unit volume. For HPMC, its density can vary depending on several factors, including the degree of substitution, molecular weight, and the specific formulation used. Generally, HPMC possesses a bulk density ranging from 0.3 to 0.6 g/cm³, with variations influenced by its viscosity grades and water content. Understanding HPMC density is crucial for formulators, as it affects the flow properties, dissolution rates, and the overall efficacy of the final product.

In the realm of food science, HPMC's solubility in methanol can be beneficial for food preservation and texture modification. As a thickening agent, HPMC plays a vital role in stabilizing emulsions and enhancing the texture of food products. The use of methanol as a solvent in the extraction process of food compounds can impact the solubility of HPMC, ultimately influencing the quality and stability of the final product.

redispersible polymer powder market share. These versatile powders help improve the performance and durability of construction materials, making them ideal for use in both residential and commercial projects.

HPMC / HYPROMELLOSE

Understanding HPMC Dispersion Applications and Benefits

The concentration of hydroxyethyl cellulose can have profound effects on the performance of a product. At low concentrations (usually below 0.5%), HEC acts primarily as a thickener, providing minimal viscosity but enough to stabilize emulsions and suspensions. Within the range of 0.5% to 2%, the viscosity properties become more pronounced, enabling better stabilization in a variety of products, such as lotions and creams.

hydroxyethyl cellulose viscosity concentration

MHEC finds its way into the food industry as a thickening agent, stabilizer, and emulsifier. It is used in a variety of products, including sauces, dressings, dairy products, and gluten-free baked goods. Its ability to retain moisture helps improve texture and extend shelf life, making it a valuable ingredient for manufacturers striving to meet consumer demand for quality and longevity in food products. Furthermore, MHEC is categorized as a Generally Recognized As Safe (GRAS) substance, making it suitable for food applications.

The Solubility of Hydroxyethyl Cellulose in Water An Overview

CIR Safety Review:

3. Paints and Coatings

HPMC is available in several grades, differentiated primarily by their viscosity, degree of substitution, and molecular weight. The choice of grade depends on the intended application

- Pharmaceuticals In the pharmaceutical industry, HPMC is commonly used as a binder and film-forming agent in drug formulations. It aids in the controlled release of active ingredients, enhancing bioavailability.

The hydroxyethyl groups enhance the solubility of HEC in cold and hot water, a trait that pure cellulose does not exhibit due to its extensive hydrogen bonding and crystallinity

. The introduction of these groups disrupts the crystalline structure of the cellulose, leading to a significant improvement in the polymer’s hydrophilicity.The cosmetic industry has also embraced HPMC for its beneficial properties. It is commonly found in skincare products, hair care formulations, and personal care items. Due to its film-forming capabilities, HPMC enhances the application and spreadability of creams and lotions, providing a smooth and silky feel on the skin. Additionally, its moisture-retaining properties help keep skin hydrated, making it a preferred ingredient in moisturizing products.

hpmc

3. Film Formation The capacity of HPMC to form films upon drying is a significant property that finds utility in pharmaceutical applications, particularly in drug delivery systems and as a coating agent for tablets.

In the beverage industry, thickeners can create innovative drink textures, offering alternatives like smoothie-like drinks or protein shakes that are both nutritious and satisfying. Additionally, they play an essential role in gluten-free and low-calorie products, where traditional thickening agents may not be suitable.

Hydroxypropyl Methylcellulose (HPMC) is a versatile and valuable polymer that plays a significant role in various industries, from pharmaceuticals to food production. This article delves into what HPMC stands for, its chemical properties, applications, and its importance in contemporary technology.

HPMC Capsules

Quality Control Measures

china hpmc factory

In the construction sector, HPMC is incorporated into cement-based products, such as tile adhesives and grout. Its water-retention capability allows these materials to maintain moisture for extended periods, promoting better adhesion and preventing cracking. Furthermore, HPMC improves the workability of these products, making them easier to apply and spread. This functionality is critical for ensuring the longevity and durability of construction materials.

Redispersible Polymer Powder An Overview

What is HPMC Made From?

Conclusion

The incorporation of HPMC in wall putty formulations offers numerous benefits that enhance both the performance and application of this essential construction material. From improved workability and adhesion to reduced shrinkage and extended open time, HPMC helps create a smooth, durable surface that meets the demands of modern building requirements. As the construction industry continues to focus on sustainability and performance, the importance of HPMC in wall putty applications cannot be overstated. Its ability to improve the quality of finishes makes it a valuable asset in achieving professional results in interior and exterior wall treatments.

Beyond its practical applications, HPMC is increasingly recognized for its environmentally friendly properties. Being derived from natural cellulose, it is biodegradable and considered safer for the environment compared to many synthetic alternatives. This aspect is particularly important in industries aiming to reduce their ecological footprint and shift towards sustainable practices.

Moreover, HEC exhibits excellent biodegradability, which aligns with the growing demand for sustainable and eco-friendly materials. Its natural origin and minimal environmental impact make HEC a favorable choice for formulations targeting the environmentally conscious consumer.

Hydroxyethylcellulose is a multifaceted polymer that plays a vital role across various industries. From pharmaceuticals to cosmetics, food production, construction, and other industrial applications, HEC's thickening, stabilizing, and moisturizing properties make it an invaluable ingredient. As research continues to uncover new applications and benefits, the importance of hydroxyethylcellulose is likely to grow, reinforcing its position as a key player in modern formulation chemistry.

What is HPMC?

Hydroxyethyl Cellulose A Versatile Polymer with Diverse Applications

Hydroxyethyl cellulose is a valuable ingredient across various industries, and finding the right supplier is essential for ensuring product quality and suitability for your specific needs. Whether you opt for online marketplaces, specialized suppliers, or local distributors, consider the factors mentioned to make an informed purchase. With the right hydroxyethyl cellulose at your disposal, you can successfully enhance the quality and performance of your formulations.

1. Concentration Higher concentrations of HPMC typically lead to increased gelation temperatures. This is due to the higher interaction and entanglement of polymer chains at elevated concentrations, which enhances gel strength.

One of the most prominent uses of HPMC is in the pharmaceutical industry. It serves as a critical excipient in the formulation of controlled-release drug delivery systems. HPMC can form a gel-like substance upon contact with water, which allows for the slow and sustained release of active pharmaceutical ingredients (APIs). This property helps improve the bioavailability of drugs and provides therapeutic effects over extended periods. Additionally, HPMC is used as a binder in tablet formulations, ensuring that the tablets maintain their integrity and provide consistent dosages.

What is Hypromellose?

Hydroxypropyl Methylcellulose (HPMC) is gaining significant attention in various industries, including pharmaceuticals, food, and construction. As a vital ingredient, its diverse applications make it a key product for businesses looking to enhance product quality and performance. This article aims to delve into the benefits and applications of HPMC, guiding potential buyers in understanding its value.

Understanding HPMC Sheets A Versatile Material in Modern Applications